FIBC or Flexible Intermediate Bulk Container is a type of industrial packaging made of woven polypropylene fabric. It is commonly used in various industries such as agriculture, mining, and construction for transporting and storing bulk materials.

One of the crucial steps in manufacturing FIBC is the sewing or stitching process. The stitching process can affect the quality and strength of the FIBC. There are several stitching patterns that can be used, depending on the specific requirements of the application.

The most common stitching patterns used in FIBC manufacturing are:

#1. Single Stitching: In this method, a single line of stitching is used to sew the FIBC. This stitching method is suitable for light to medium-duty applications.

#2. Double Stitching: This method uses two lines of stitching to sew the FIBC, providing additional strength and stability. This stitching method is suitable for heavy-duty applications.

#3. Safety Stitching: This stitching method is used in FIBC that will be subjected to extreme stress or pressure. It involves sewing the FIBC with two lines of stitching and an additional safety stitch for added durability.

#4. Chain Stitching: This stitching method involves a series of interlocking chain stitches that provide added strength and stability to the FIBC.

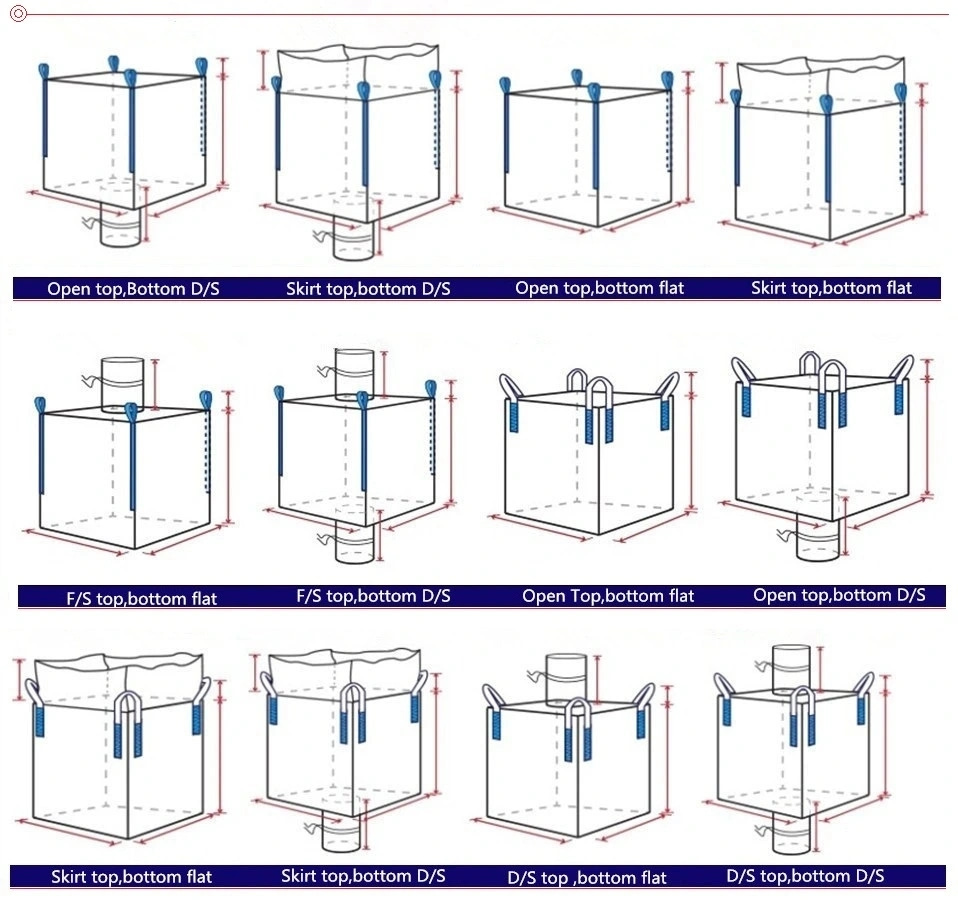

In addition to the stitching method, there are also various types of FIBC that can be made, depending on the specific requirements of the application. These include:

#1. U-Panel FIBC: This type of FIBC has a U-shaped panel on both sides, providing a more stable base for the bag.

#2. 4-Panel FIBC: This type of FIBC has four panels on each side, providing a more uniform shape for the bag.

#3. Circular Woven FIBC: This type of FIBC is made using a circular weaving technique, resulting in a seamless bag with no side seams.

Overall, the stitching method and type of FIBC used can significantly impact the quality and durability of the FIBC. It is essential to consider these factors when selecting the appropriate FIBC for your specific application.