Bulk bags are made of polypropylene fabric, a strong, durable, and thermoplastic polymer FIBC material that’s resistant to moisture, chemicals, and UV radiation. Coatings provide extra protection, and bags feature woven polypropylene lifting loops for easy handling.

There are a number of bulk bag specs that are designed to meet Department of Transport (DOT) requirements for transport, including the:

- Thickness of individual threads (denier)

- Fabric weight (GSM)

- Strength of the yarn and fabric.

From these engineering specs, each bag is specifically designed to pass a number of stress tests, including drop and jerk forces, that could affect the integrity of each bag during transport.

When purchasing an FIBC, the most important bulk bag spec is the bag capacity (or bag size), which can range from 500 to 4,000 pounds when filled.

Also, the styles and types of FIBC bags should be considered when choosing an FIBC to meet your product storage and transport applications:

- Type A FIBC: No Electrostatic Protection

- Type B FIBC: Surface Breakdown Voltage of <6kV

- Type C FIBC: Electrically Conductive or Groundable

- Type D FIBC: Static Dissipative

Within these FIBC bag types, you will find different styles to meet your bagging needs, including rectangular or four-panel bags, duffle top bags, and circular bulk bags. For each bag style, the manner in which they are constructed will be similar, other than the type of material, size, and shape.

If you’re unsure which of these bags you need, get in touch with the team here at Palmetto Industries so we can discuss your needs further.

The FIBC Bags Manufacturing Process

The FIBC bags manufacturing process we take is as follows:

- Extrusion

- Weaving

- Vacuuming

- Lamination

- Printing

- Cutting

- Sewing

- Final Testing

Let’s take a look at each of these steps in more detail so you can see exactly how we optimize your product for your needs:

1. Extrusion: Feeding in the FIBC material

The making of a bulk bag begins with the feeding of polypropylene (PP) resin and other additives into an extruder to produce PP tapes that vary in thickness and width.

The melted resin forms PP sheets that are stretched by rollers, then cut.

2. Weaving

The tapes are then wound onto bobbins to start the weaving process which will create the FIBC fabric.

The fabric weaving is performed on special looms to make either circular shaped bags or U-panels for the various other FIBC bag styles.

3. Vacuuming

If the fabric is to be coated, the bags are vacuumed to release dust particles, and the bag is then passed through a static eliminator.

4. Lamination

A lamination process then applies a protective coating of polypropylene which will increase the bags’ resistance to moisture and sifting. Breathable fabric bags are left uncoated.

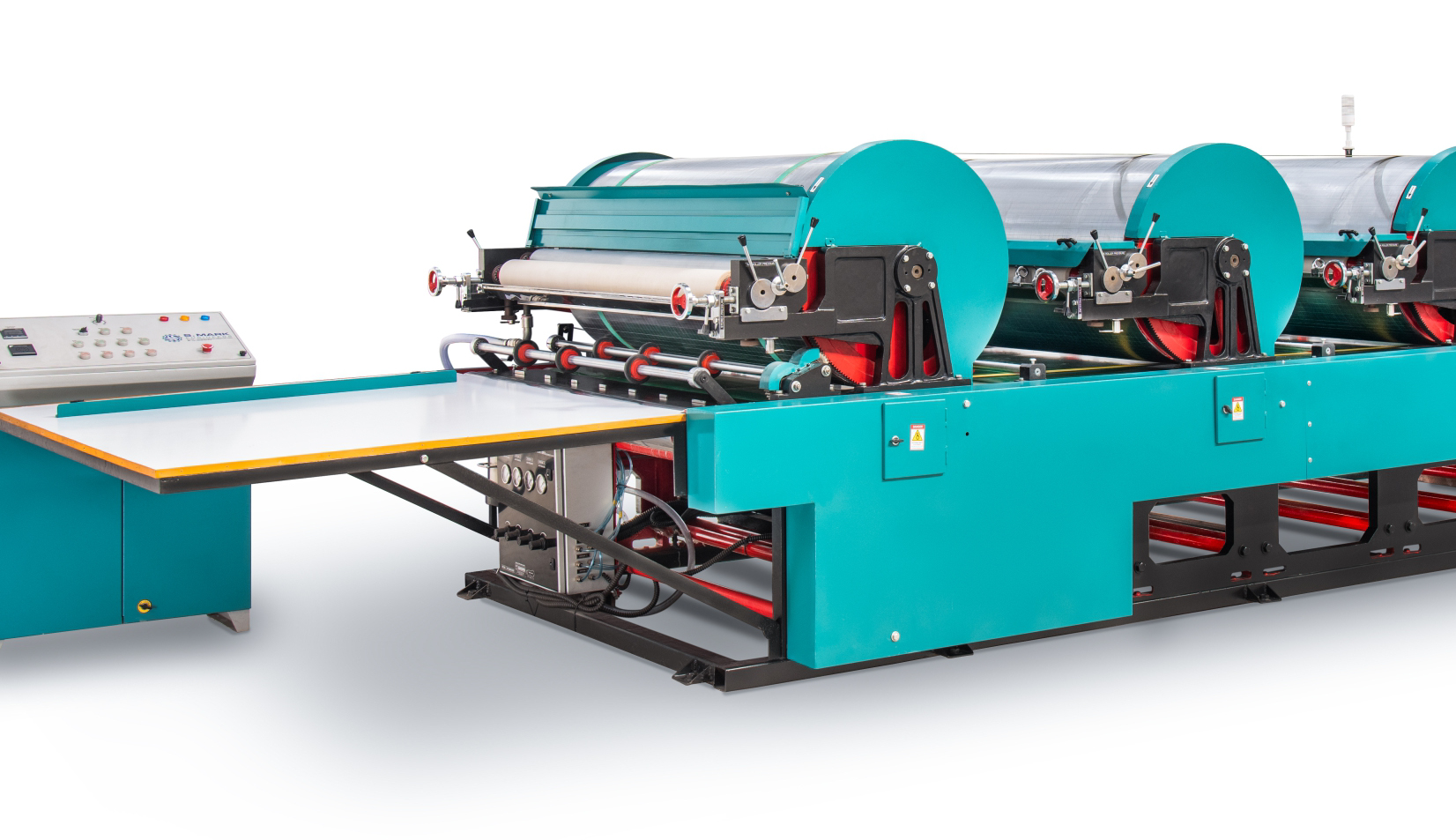

5. Printing

At this point, the bags are printed with an FDA-approved printing ink, suitable for food contact. The ink that is used will dry quickly to eliminate smears or running.

6. Cutting

Next, a computer program controls the precision cutting of the woven fabric from the rolls into the required sizes for the bag assembly process.

7. Sewing

Finally, highly-trained employees complete the manufacturing process by sewing the fabric pieces together to create each bulk bag. All bags are sewn in an FDA-approved clean room to maintain sanitation requirements.

8. Final Testing

While we continuously QA our bulk bags through the manufacturing process, at this stage, filler cords are sewn into the seams and the bags will move on through different types of testing to final approval.

Key Takeaways On The FIBC Manufacturing Process

The FIBC manufacturing process involves several key steps, but, depending on the specific requirements, additional processes may be applied.

For instance, coatings like polyethylene or polypropylene can be applied to enhance moisture resistance, and printing machines may add logos or other information onto the fabric’s surface.

After the fabric is woven and any optional coatings or printing are applied, it is ready for bag construction and final inspection. This meticulous manufacturing process ensures that FIBCs meet industry standards and can withstand the rigors of transporting and storing bulk materials effectively.