|

Product:

|

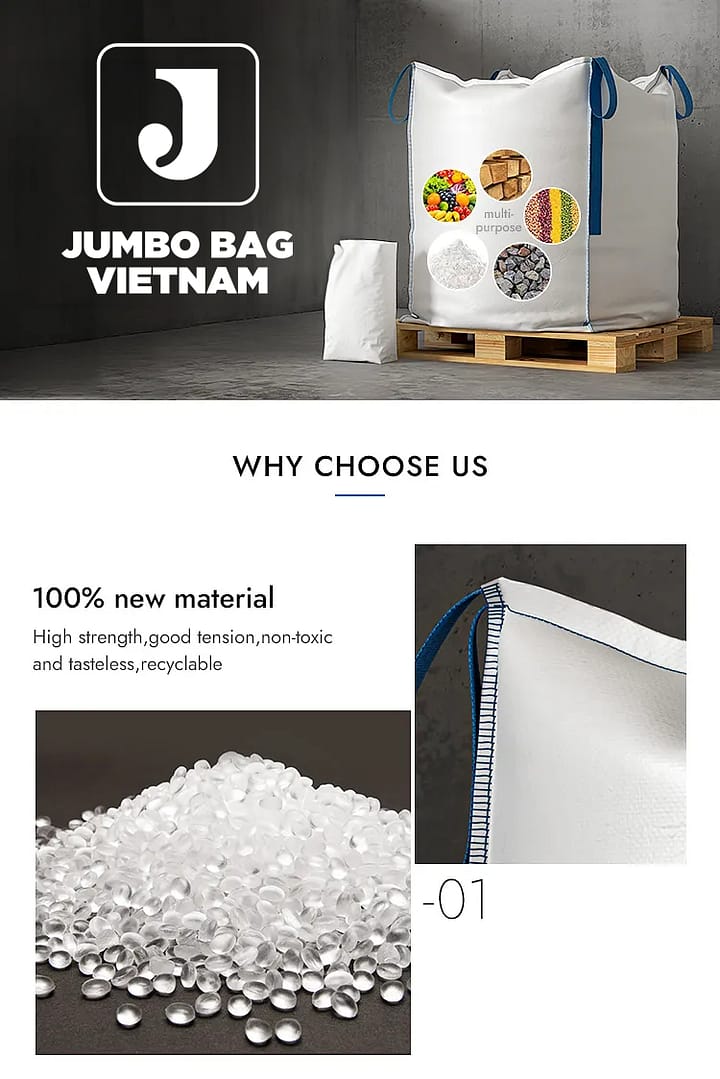

PP FIBC Bag, PP Bulk bags

|

|

Material:

|

100% new PP polypropylene

|

|

Weights/m2:

|

42 g M2-200 g m2

|

|

Color :

|

White, customizable: red, yellow, blue, green, gray, black and other colors

|

|

Width:

|

Width 20cm-150cm, According to your request

|

|

Length:

|

According to your request

|

|

Loading capacity:

|

1000kg,1500kg,2000kg or as your requirements

|

|

Printing:

|

Offset printing, gravure printing,BOPP printing, full color printing

|

|

Bottom:

|

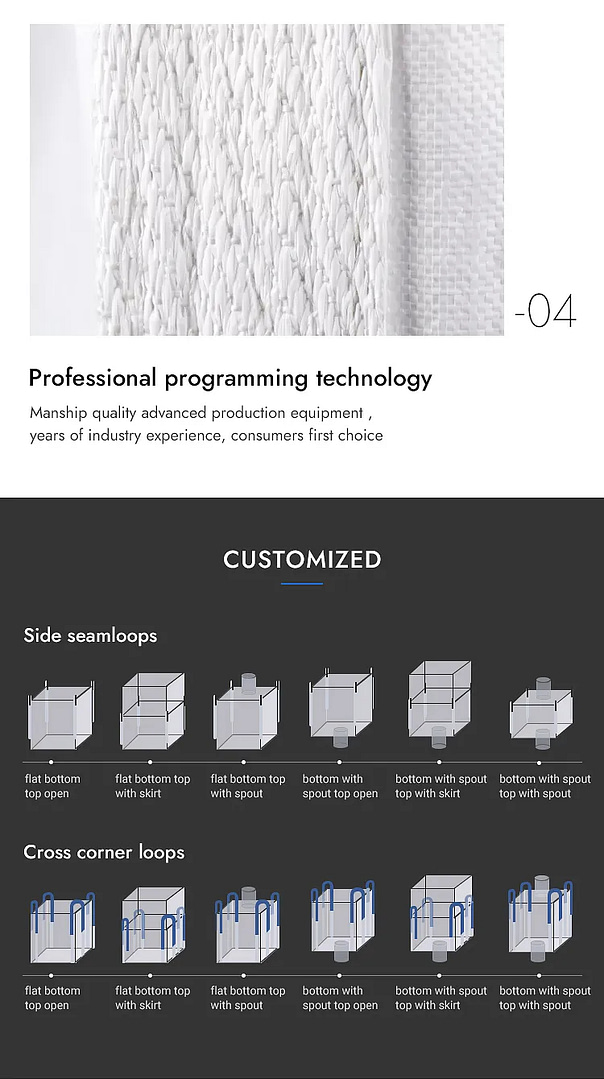

Single fold, double fold, single stitch, double stitch or upon your request

|

|

Feature:

|

Dustproof, strong tensile/impact resistance, electrical insulation, environmental resistance

|

|

Packaging:

|

Dustproof, strong tensile/impact resistance, electrical insulation, environmental resistance

|

|

Usage:

|

Packed rice, flour, sand, corn, seeds, sugar, garbage, animal feed, asbestos, fertilizer and so on

|

|

Sample time:

|

5 to 10 days

|

|

Production time:

|

10 to 30 days

|

|

Monthly capacity:

|

350,000 tons / 2,000,000 pieces

|

|

MOQ:

|

1000pcs stock size ,5000pcs customized size

|

|

Delivery Time:

|

10-30 days after placing an order or negotiating

|

|

Top:

|

Hot, cold cut, serrated or rolled

|

|

Payment term:

|

T/T, 30% down payment and 70% paid before delivery.

|

Our PP Jumbo Bags boast exceptional specifications, including customizable sizes, high-quality polypropylene, a 5:1 safety factor, and printing on up to four sides. These bags come in various sizes and fabric types, such as coated, uncoated, breathable, laminated, layered, or any combination thereof, tailored to your preferences.

Key Features Our PP Jumbo bags are lightweight yet durable, ideal for transporting both dry and liquid bulk materials. Singhal Industries exports these bags to the US, UK, UAE, Canada, and Australia as needed.

Environmental Benefits As an eco-friendly manufacturer, Singhal Industries produces PP jumbo bags that are recyclable and versatile, reducing environmental impact and serving various industries effectively.

Recyclability and Eco-friendliness PP jumbo bags are recyclable, reducing landfill burden and aligning with modern environmental concerns. They are a responsible choice for packaging needs.

Efficient Handling and Promotion Designed for ease of use, these bags have integral lifting loops, eliminating the need for pallets. Their large surface area is perfect for displaying logos and brand information, turning them into effective promotional tools.

Versatility and Practicality PP jumbo bags are adaptable for various industries, offering ease of storage, filling, discharge, and handling. They are suitable for transporting powdered goods, foodstuffs, granulated materials, minerals, cement, pharmaceuticals, chemicals, and fertilizers.

Types of PP Jumbo Bags

Single Loop PP Jumbo Bags: Ideal for bulk materials like cement or fertilizers, with or without a PE inner lining.

Two Loop Jumbo Bags: Versatile for various contents, including chemicals, fertilizers, minerals, and food grains.

Four Loop Jumbo Bags: Suitable for transporting chemical powders, food grains, and fertilizers.

Builder Jumbo Bags / Q Bags: High-quality polypropylene bags with shape retention and high stackability, ideal for construction materials.

UN Certified Jumbo Bags: Designed for carrying heavy and volatile substances with a 6:1 safety ratio.

Ventilated FIBC Bags: Breathable and moisture-resistant, ideal for perishable items like vegetables.

Dissipative FIBC Bags: Made from antistatic fabric for transporting flammable powders, provided the load is not contaminated.

Choosing the Right Jumbo Bags Selecting suitable PP Jumbo Bags is crucial for efficient and safe material handling, especially for transporting powdered or flammable goods.

Market Trends for PP Jumbo Bags PP Jumbo Bags are gaining popularity across various industries due to their benefits.

Supply Chain Expansion: FIBC Bags ensure material protection, especially for hazardous substances.

Environmental Awareness: Made from heavy polypropylene fabric, these bags are eco-friendly and reduce the need for multiple sacks.

Industrial Growth: PP Jumbo bags are essential for safe shipment in infrastructure projects.

Features

Protection Against External Factors: UV rays, moisture, pests, and humidity.

No Need for Pallets or Secondary Packaging: Streamlines packaging and reduces costs.

Optimal Space Utilization: Efficient use of storage and transportation space.

Enhanced Moisture Protection: Liners for additional defense against moisture.

Strength and Flexibility: Lightweight, robust, and durable for safe transportation.

Customizable Finishes: Coated or uncoated options.

Convenient Labeling: Document pouches for easy labeling.

Versatile Handling: Various options for filling, discharging, hauling, and lifting.

Anti-Static Properties: Safe packaging of materials sensitive to static electricity.

Safe for Hazardous Materials: Non-toxic, suitable for hazardous chemicals.

Space-Efficient Delivery: Can be folded flat and baled for optimized delivery logistics.

Leakage-Free Transport: Ideal for granules, small particles, and powders.

Smooth Filling and Emptying: Flaps, skirts, valves, and ropes for easy processes.

Innovative Design for Higher Capacity: Accommodates more material than dimensions suggest.

Efficient Loading and Unloading: Integral lifting loops expedite operations.

Advantages

Eco-Friendly: Fully recyclable.

Cost-Effective: Saves expenses.

High Weight-Bearing Capacity: Suitable for bulk manufacturing industries.

Promotional Opportunity: Large size for advertising.

Space-Efficient Storage: Optimizes warehouse space.

Waste Reduction: Contributes to reducing waste flows.

Enhanced Logistics: Improves overall logistics.

Versatile Substitution: Economical alternative to traditional packaging.

User-Friendly: Easy to handle.

Durable and Long-Lasting: Ensures safe transportation over extended periods.

Applications PP Jumbo bags are used across various industries, including:

Chemical

Steel

Fertilizer and Mineral

Mining

Food-based

Petroleum

Construction

Plastic-based

Cement and Salt

Pigments and Fillers

Oil and Natural Gas

Pharmaceutical

Resin

Nut

Fine powders

Paper

Specifications Tam Duong Pack offers PP Jumbo bags with the following specifications:

Safe Working Load (SWL): Ranging from 500 to 2000 kg.

Size: Customizable as per requirements.

Safety Factor: 5:1 or as per specific needs.

Material: UV-stabilized Polypropylene.

Thickness: Ranging from 40 to 200 Micron.

Certification: All bags are UN certified, ensuring safety and quality.

Printing: Up to 4 colors and on up to 4 sides.

Liners: Available in Normal, Bottle Shaped, Glued, or Sewn variations.

Color: Customizable in various colors based on requirements.

Dimensions: Standard sizes like 85 cm x 85 cm x 11 cm, 90 cm x 90 cm x 90 cm, 90 cm x 90 cm x 125 cm, and more, as needed.

Height: Adjustable from 75 cm to 200 cm, or as per specific requirements.

Fabric: Options include Coated, Uncoated, Laminated, Unlaminated, Ventilated, or customized as needed.

Tam Duong Pack’s team of experts can provide various sizes, shapes, styles, and colors of FIBC bags to meet your unique specifications.

Reviews

There are no reviews yet.