Bulk bags, or FIBCs, are large flexible containers that are commonly used to package bulk goods such as construction materials, agricultural produce or mining ore. They can be tailor-made to suit the needs of different customers and at Custom Bulk Bags, we offer a number of customisable features.

One such feature is a coating on the external fabric of the bags. In a nutshell, a coated bag has an extra plastic film that is attached to the inner or outer surface of the bag to add an extra layer of protection and moisture resistance. Choosing between a coated and uncoated bulk bag will depend on what the bags are going to be used for.

Our expert team is available to help customers choose the best bag for their products and needs. Making the right purchasing decision can help to lower costs and make sure you get the most out of your FIBCs. Let’s have a look at what coated and uncoated bulk bags are used for to help you make the right choice.

What are coated bulk bags used for?

Coated FIBCs are used to package bulk goods that are very fine in consistency. Very small particles, such as powders, sand or minerals, can escape through the gaps in the weave of the bulk bag’s fabric. Adding a coating to the bag helps to prevent this from happening.

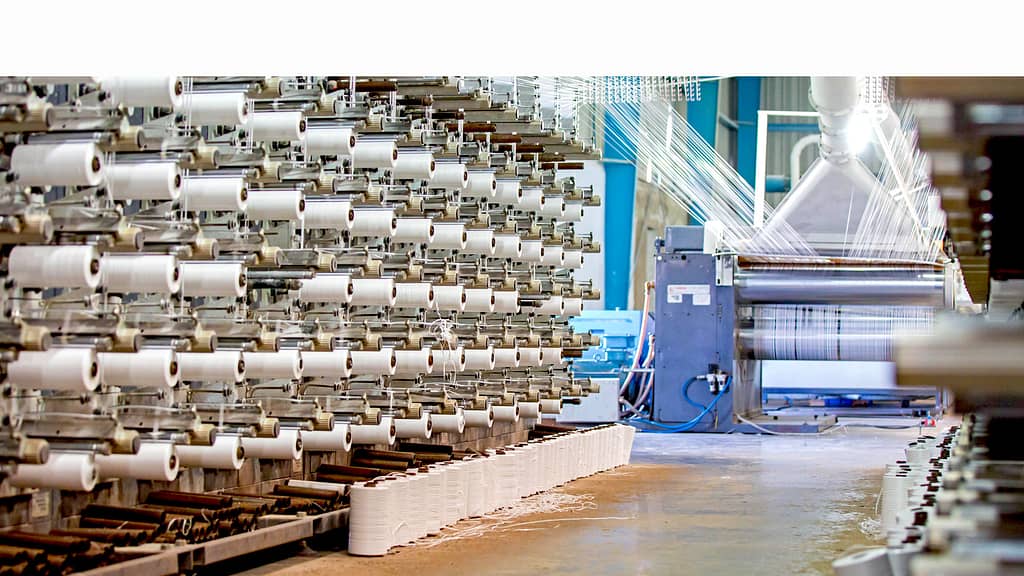

FIBCs are made from woven polypropylene. Thin tapes of polypropylene are woven together to create a strong, yet lightweight, fabric. Polypropylene is a thermoplastic that has a very high weight to strength ratio, making it an ideal choice of durable, affordable packaging.

When FIBCs are coated, an additional polypropylene film is used as a lining. This is added to the woven polypropylene fabric before the panels are sewn together. Including a coating helps to give better protection for very fine or powdery substances contained within the packaging.

What are uncoated bulk bags used for?

Uncoated bags allow air and moisture to pass through the fabric more freely. This makes them suitable for items that require some airflow and which are not altered by moisture entering the bag. Mining ore, construction rubble and firewood are just a few examples of the types of goods that can be safely packed in an uncoated bulk bag.

If the particle size of your product is larger than 120 microns, then no coating is necessary. This includes grains, seeds, straw, maize or animal feed. Products that are in a granular form, including rice and beans, can be packaged in uncoated bulk bags. For goods that have a particle size that is smaller than 120 microns, a lined or coated FIBC will probably be necessary.

Should I choose a coated or uncoated bulk bag?

To get a better idea of how coating can help, think of a FIBC filled to the top with fine sand. Imagine what would happen if you hit the side of the bag. You should expect to see a small dust cloud emerge from the bag upon impact. Not only does the fine sand get wasted as it seeps through the fabric, but it also gets lodged in the fabric of the bag itself. It can be very difficult to remove these small particles from the bag’s surface, meaning that it may not be possible to later reuse or recycle that particular bag.

Opting for a coated FIBC will help to alleviate these issues. A polypropylene film that is one millimetre or less is laminated onto the fabric to make a coating. It gives the fabric a smooth, glossy appearance. This coating seals the gaps in the weave, eliminates dust and has the additional benefit of reducing fraying.

The coating provides a barrier against dust and other contaminants. It also offers some protection against moisture, although a coated bag is not considered to be waterproof. They are ideal for products that need some protection against moisture. This includes goods in a variety of forms, such as crystals, granules and flakes (e.g. flour, salt, cement, sugar and fine minerals).

Coating, although adding to the overall cost of the bag, is still an economic option. The coating adds very little additional weight to the packaging, which is beneficial for keeping logistical costs down. However, if your goods do not require this additional layer of protection, then it is better to choose an uncoated bag and save on costs.

Consult a bulk bag expert

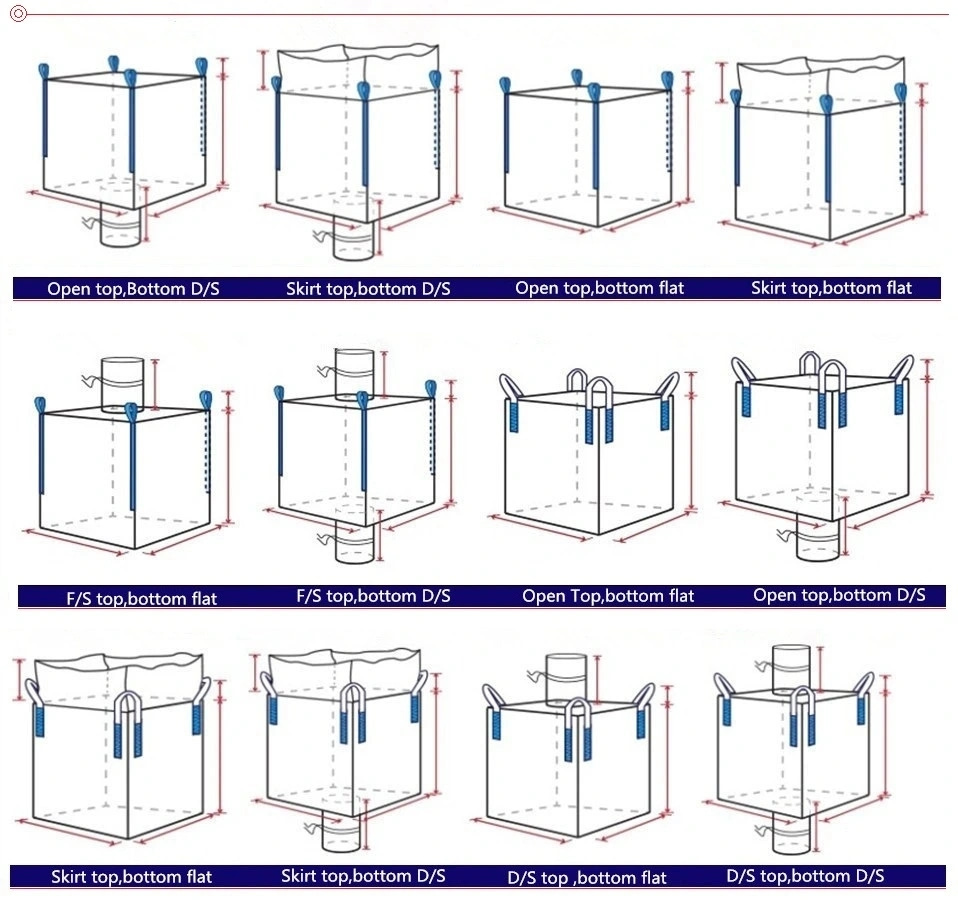

Our friendly team of experts is on hand to answer your questions about the best bulk bag design for your needs. Our bags come in a variety of styles, shapes and have customisable features that ensure your bulk bags work well for you.

There are different styles of bulk bags available. All these can be coated or uncoated, depending on what you intend to put inside the bags. When choosing your bulk bag, think about the density of your product, whether you’ll be using the bag for fine or course materials.

Also consider the moisture sensitivity of your product and other characteristics, such as whether it is free-flowing or prone to build up. FIBCs are the most affordable and practical way to package bulk goods, but make sure you are using the right one for your product. For more information about our bulk bags, please contact us today.

___

Custom Bulk Bags is a leading South African manufacturer of woven polypropylene bags for various industries, such as mining, chemicals and food. We are able to produce over 3.5-million bulk bags per year, keeping our customers in-stock at all times. Our bags adhere to the highest levels of quality as a result of our stringent in-house testing and quality control programmes.